Chapter 2 is a full-service contract manufacturer with a long history of innovation and expanding its capabilities. We are proud of our ability to source, machine, assemble and monitor many assembly projects. Our team continues to respond to demand, offering fabrication and painting services, CNC and precision machining, and more. Chapter 2 is also committed to supporting the renewable energy sector through our expertise in manufacturing components for the green energy industry.

CNC Machining for Renewable Energy

CNC machined parts are widely used for renewable energy, such as bioenergy, solar power, offshore wind, onshore wind, and hydropower. CNC machining leverages computer-aided design or CAD to mass-produce highly accurate parts. In the renewable energy industry, these precision components increase the quality and efficiency of generating power. Benefits include:

- Precision and consistency

- Extremely accurate parts

- High-quality finishes free of errors and defects

- Strong, durable components that withstand constant use

Renewable Energy Components

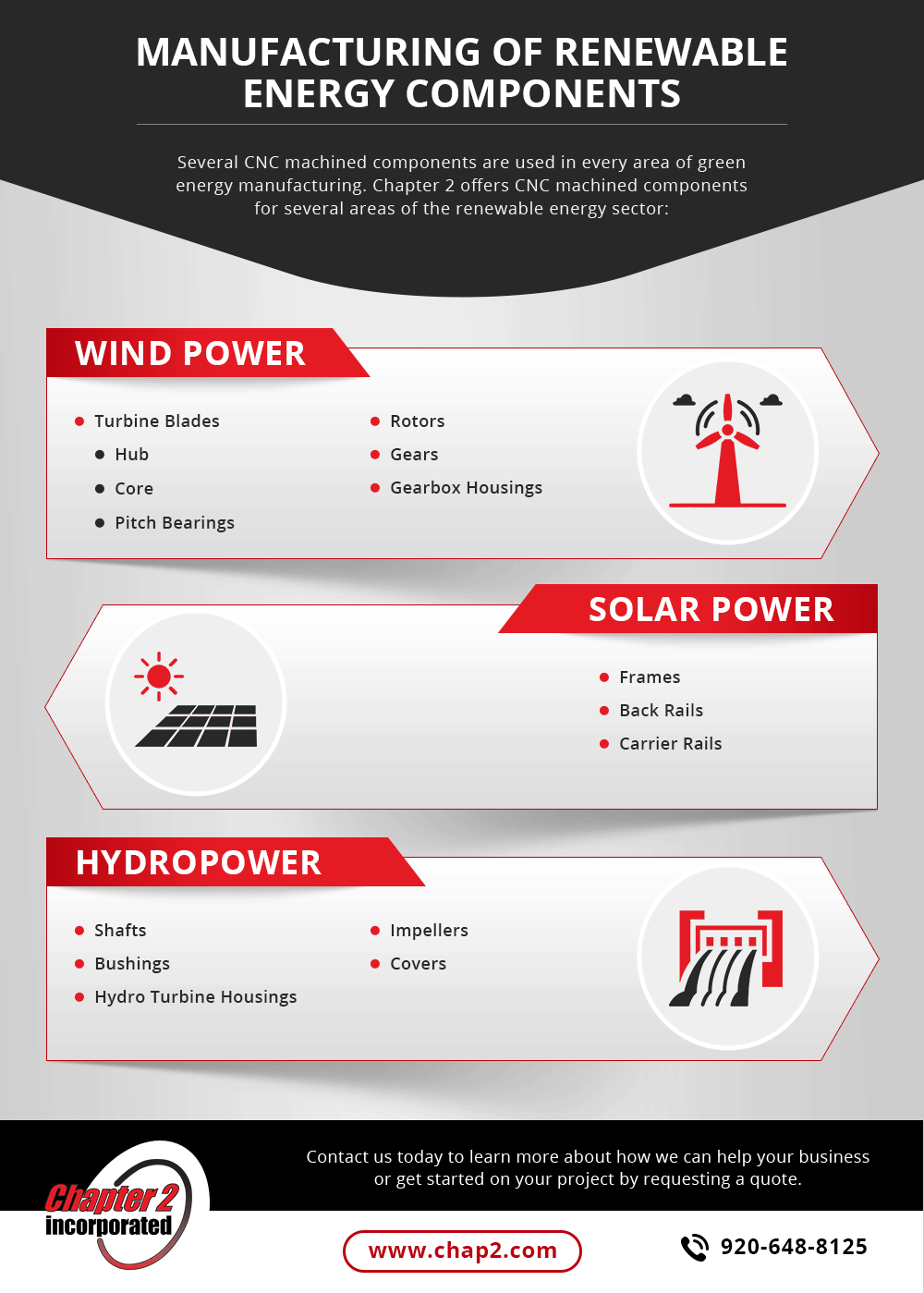

Several CNC machined components are used in every area of green energy manufacturing. Chapter 2 offers CNC machined components for several areas of the renewable energy sector.

Wind Power

Metal and carbon fiber machining creates turbine blades that withstand significant wind pressure while maintaining dimensional stability without degradation from wear and tear. High accuracy is achieved with CNC machining that ensures critical mobility for all components, such as the hub, core, and pitch bearings. Multipurpose lathes create rotors, gears, and gearbox housings.

Solar Power

It takes several components to create solar panels. The frames, back rails, and carrier rails all play critical roles in solar power generation’s efficiency and efficacy. We employ several CNC processes to create solar power parts, like cutting and drilling. CNC machining improves efficiency in floor space and labor utilization, leading to increased production capabilities, quality, and cost-efficiency.

Hydropower

Hydropower components include simple shafts and bushings, hydro turbine housings, impeller, and covers. Each of those parts must be able to withstand the tremendous pressure and abrasive forces from the water. Carbon and stainless steel are ideal for this. CNC machining like turning, line boring, and milling is used for individual components as well as massive dam and hydropower station gates.

Our Capabilities for Renewable Energy Manufacturing

Chapter 2 offers many capabilities for manufacturing renewable energy parts, including the following:

- CNC milling: Our automated multi-axis milling equipment accommodates various features and materials at significant cost savings.

- CNC turning: Our many turning processes allow us to form complex external geometries, compound internal features, and intricate thread patterns meeting the tightest tolerances at accelerated cycle times.

- Welding and assembly: We fabricate parts with materials such as steel, aluminum, or stainless steel using MIG, TIG, robotic, and aluminum welding methods. Our capabilities encompass other fabrication and assembly services, including prototyping, torching, plasma cutting, water jet cutting, and more.

- Painting: Our painting services include all pre-finishing tasks, such as custom masking, blasting, grinding, smoothing, priming, coating, air drying, and baking. We also offer two component and one urethane primer and a wide selection of coatings.

- Workholding: Workholding services include checking, machining, testing, welding, broaching, assembling, pressing, and inspecting manual, pneumatic, and hydraulic fixtures.

- Tool and die: Our wide range of custom dies include cutting, trimming, shearing, compound, progressive, transfer dies, and many others.

Our versatile team of experts is not only experienced in component manufacturing, but they can also help you with manufacturing design.

Custom Solutions at Chapter 2, Inc.

Chapter 2 is an industry-leading contract manufacturer committed to providing the highest quality products and services at competitive prices. We believe in reinvesting in our company to stay on the cutting edge of technology, process, education, and quality systems. Contact us today to learn more about how we can help your business or get started on your project by requesting a quote.