In today’s competitive landscape, businesses are constantly seeking ways to improve efficiency, reduce costs, and enhance product quality. One powerful tool that can help achieve these goals is automation. By automating repetitive tasks, businesses can free up valuable resources, increase productivity, and ensure consistent results.

At Chapter 2, we’re committed to helping our clients unlock the full potential of automation. Our custom machine-building expertise allows us to design and implement innovative solutions that address your unique needs. In this blog post, we’ll explore how our custom machine tending solutions can revolutionize your business operations.

Custom Automation Solutions Tailored to Your Needs

One of the key advantages of working with Chapter 2 is our ability to provide highly customized automation solutions. Our team of experienced engineers possesses a deep understanding of both machining processes and robotic technology. This expertise enables us to design and build automated machining cells that are perfectly suited to your specific requirements.

Whether you need a simple solution for a single machine or a complex system for an entire production line, we can deliver a tailored solution that meets your exact needs. Our engineers will work closely with you to understand your processes, identify areas for improvement, and develop a customized automation strategy.

Chapter 2’s In-House Application

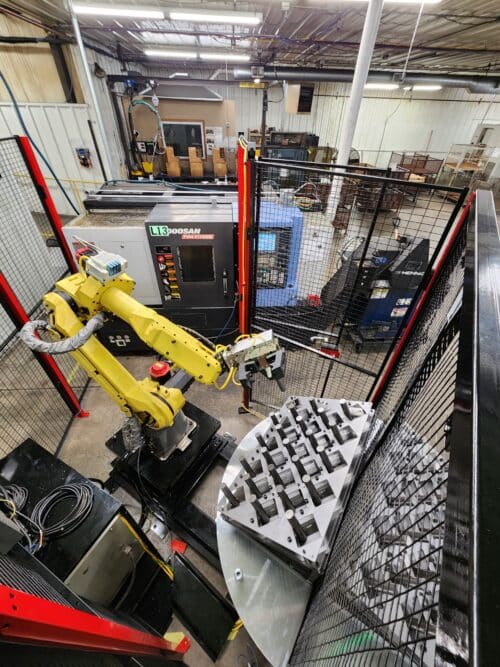

To demonstrate our capabilities for automated machine-tending, we’ve successfully implemented this in our own manufacturing facility. Pictured below is a robot tasked with tending our CNC machining center, efficiently loading and unloading components while maintaining high production rates.

Streamlined Project Management for an Improved Customer Experience

Streamlined Project Management for an Improved Customer Experience

Implementing an automation solution can be a complex undertaking. That’s why at Chapter 2, we prioritize streamlined project management to ensure a smooth and efficient process. Our team will handle every aspect of your project, from design and engineering to installation and commissioning.

Here’s a breakdown of our project management process:

- Needs Assessment: We’ll work with you to understand your specific requirements and goals.

- Design and Engineering: Our engineers will develop a customized automation solution that meets your needs.

- Manufacturing: We’ll fabricate and assemble the automated system in our state-of-the-art facility.

- Installation and Commissioning: Our team will install and test the system to ensure it operates flawlessly.

- Training and Support: We’ll provide comprehensive training to your staff so they can effectively operate and maintain the system.

By handling every step of the process, we can minimize disruptions to your operations and ensure that your automation solution is delivered on time and within budget.

The Benefits of Custom Machine Tending

Investing in custom machine tending can offer numerous benefits for your business, including:

- Increased productivity: By automating repetitive tasks, you can free up your workforce to focus on more value-added activities.

- Improved quality: Automation can help reduce human error and ensure consistent product quality.

- Reduced costs: By streamlining your production processes, you can lower your operating costs and improve your bottom line.

- Enhanced flexibility: Custom automation solutions can be easily adapted to changing production needs.

- Competitive advantage: By adopting automation, you can gain a competitive edge in your industry.

If you’re looking to improve your business operations and achieve long-term success, custom machine tending may be the right solution for you. At Chapter 2, we’re dedicated to helping companies realize the full potential of automation.

Contact us today to learn more about how our custom machine tending solutions can benefit your business.