Manufacturing and Industrial Automation

Revolutionizing Manufacturing Through Automation

In today’s fast-paced manufacturing environment, staying competitive means finding ways to produce more efficiently, with greater precision, and at a lower cost. For many companies, this often involves automating repetitive processes, speeding up throughput, or freeing up skilled workers to focus on more complex tasks. Chapter 2 brings years of expertise in manufacturing and industrial automation, offering solutions that seamlessly integrate with your operations to improve productivity and profitability.

As your automation partner, Chapter 2 can provide you with years of expertise for:

- Custom Robot Cells

- Custom End of Arm Tooling (EOAT) Solutions

- Equipment Customization and Retrofitting Services

- Custom Inspection/Testing Systems

- Industrial Optimization through Custom Automation

Partner with Chapter 2 for excellence in automation. Contact us at 920-648-8125 or request a quote and discover how our expertise can enhance your manufacturing processes through automation. Our team stands ready to develop customized automation solutions that meet your specific requirements while maintaining the highest standards of precision and reliability.

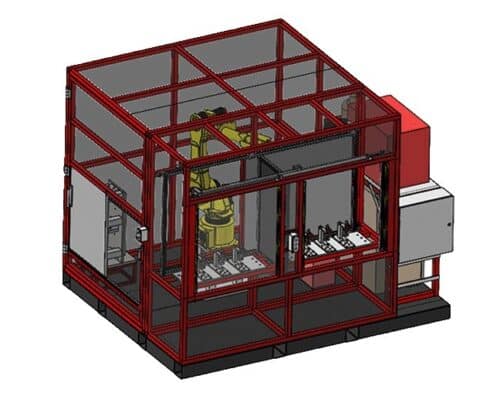

Custom Robot Cells

Robot operating cells represent a transformative solution for modern manufacturers facing labor shortages and increasing production demands with the utilization of robotic systems to work alongside your equipment. By implementing robotic automation to handle the repetitive tasks within your process, your most valuable assets, your employees, can focus on higher skilled tasks. These systems can operate consistently through multiple shifts, dramatically increasing your machine utilization while maintaining precise handling requirements.

What sets today’s robotic solutions apart is their adaptability and ease of use. Users can quickly switch between different part runs using intuitive interfaces, and built-in error detection helps prevent costly crashes and mistakes.

Common applications where Robotic cells have proven to be of value are

- Welding

- Assembly

- Material Handling

- Machine Tending

- Picking and Palletizing

- Cutting, Grinding, Deburring

These systems can be scaled to match your current needs while accommodating future growth. The result is a more efficient, safer, and more profitable operation that can compete effectively in today’s demanding manufacturing environment.

Custom End of Arm Tooling (EOAT)

End of Arm Tooling (EOAT) is a solution where custom-designed attachments are affixed to the end of robotic arms, enabling precise manipulation of objects in various manufacturing processes. Chapter 2 specializes in creating robust EOAT solutions tailored for applications such as material handling and part manufacturing. These tools encompass gripper systems, vacuum cup systems, magnetic devices, and quick-change mechanisms, all engineered to enhance speed and accuracy in automated operations

Your manufacturing and assembly process can reap the benefits of a Chapter 2 designed EOAT solution which includes:

- Precise Part Handling: Achieve consistently accurate placement with tooling designed specifically for your application

- Reliable Performance: Maintain steady production cycles with robust, purpose-built end effectors

- Asset Protection: Integrated sensing and controlled movements help prevent damage to valuable molds and equipment

- Enhanced Quality Control: Purpose-designed grippers and handlers ensure parts maintain their integrity throughout the process

- Adaptable Solutions: Versatile tooling options allow for multiple part variations and future production flexibility

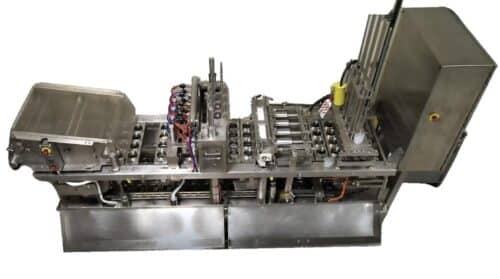

Machine Customization and Retrofitting

Machine customization is the evaluation, modification and improvement of existing machines.

It refers to adding new engineered features to an existing machine so that it has a new level of automation and/or improved functionality.

Retrofitting refers to making use of older generation machinery by upgrading it to work at a higher efficiency or modifying it to be repurposed for other use. Retrofitting can be seen as a “conservative” approach but is becoming more popular as companies strive to be more fiscally responsible.

Common upgraded features for either application may include

- Replacing/Upgrading obsolete parts, from wiring, to sensors, bearings, castings no longer available, servo motors and actuators. Air cylinder upgrades.

- Adding HMI (Human Machine Interface) for easier interaction and trouble shooting

- Efficiency counters/parts counters

- Upgrading controls and safety devices to work with modern safety equipment

- Advancements in bearings and slide materials and technology

- In process part marking, visual inspection, labeling, ect

- Automating load and unload processes on manual machines

- Updating sensor types to modern equivalents, ie mechanical to infrared, laser, capacitive or inductive.

- PID upgrades for flexibility in adjustment and monitoring.

Custom Inspection and Testing Systems

Custom inspection and testing systems are highly specialized inspection solutions designed to enhance quality control and operational efficiency in manufacturing environments. These systems can utilize more traditional contact-electronic, air-to-electronic systems or more advanced contactless measurement and vision system technology.

These systems are often integrated with other forms of automation or data-driven technologies, enabling real-time feedback, and seamless process adjustments. Customization allows the system to be tailored to unique manufacturing needs, accommodating specific part geometries, inspection criteria, and production speeds. With features like pattern recognition, barcode reading, surface analysis, and 3D imaging, leak testing, custom inspection systems deliver unparalleled accuracy and reliability, reducing errors and waste while improving throughput and product consistency.

At Chapter 2, our custom designed inspection and testing systems ensure the highest level of performance quality and reliability for your operations. We understand that in the manufacturing world no one solution fits all. So, whether you need a mechanically driven in-line or end-of-line test, or an automated driven solution powered by a vision, Chapter 2 can be your partner for a customized solution that is easier, more reliable and works for you.

Industrial Process Optimization

Industrial process optimization is a critical strategy for improving the efficiency and effectiveness of manufacturing and production systems. It often involves a detailed analysis of existing workflows, identification of inefficiencies, and implementation of changes to streamline operations. Key aspects of our process optimization include:

- Assessment and DesignAssessing the specific requirements of your needs. This involves understanding the workflows, safety protocols, and operating goals. Our engineering and applications teams will then create a tailored solution that aligns with the client’s objectives and integrates well with existing equipment and infrastructure.

- Simulation and TestingDepending on the scope of project software simulations or functional component testing will help anticipate potential problems or inefficiencies before deployment and validate the process prior to final build and installation.

- Implementation and ConfigurationSystem components are physically installed at the site, including wiring, controllers, sensors, and machinery. After installation, the system is configured to work according to the design specifications, followed by rigorous testing to ensure everything functions smoothly.

- Maintenance and SupportOperators and technicians are trained on how to use, troubleshoot, and maintain the system effectively. After the system is in place, ongoing monitoring, maintenance, and troubleshooting ensure optimal performance. This can include remote diagnostics and updates.

Chapter 2’s overall goal when working with its customers is to create a more competitive and sustainable production environment that delivers high-quality products while maintaining operational flexibility and minimizing operational costs. Whether the scope is a specific workcenter, workspace or an entire facility Chapter 2 is here to help.

Why Choose Us?